Quality Assurance

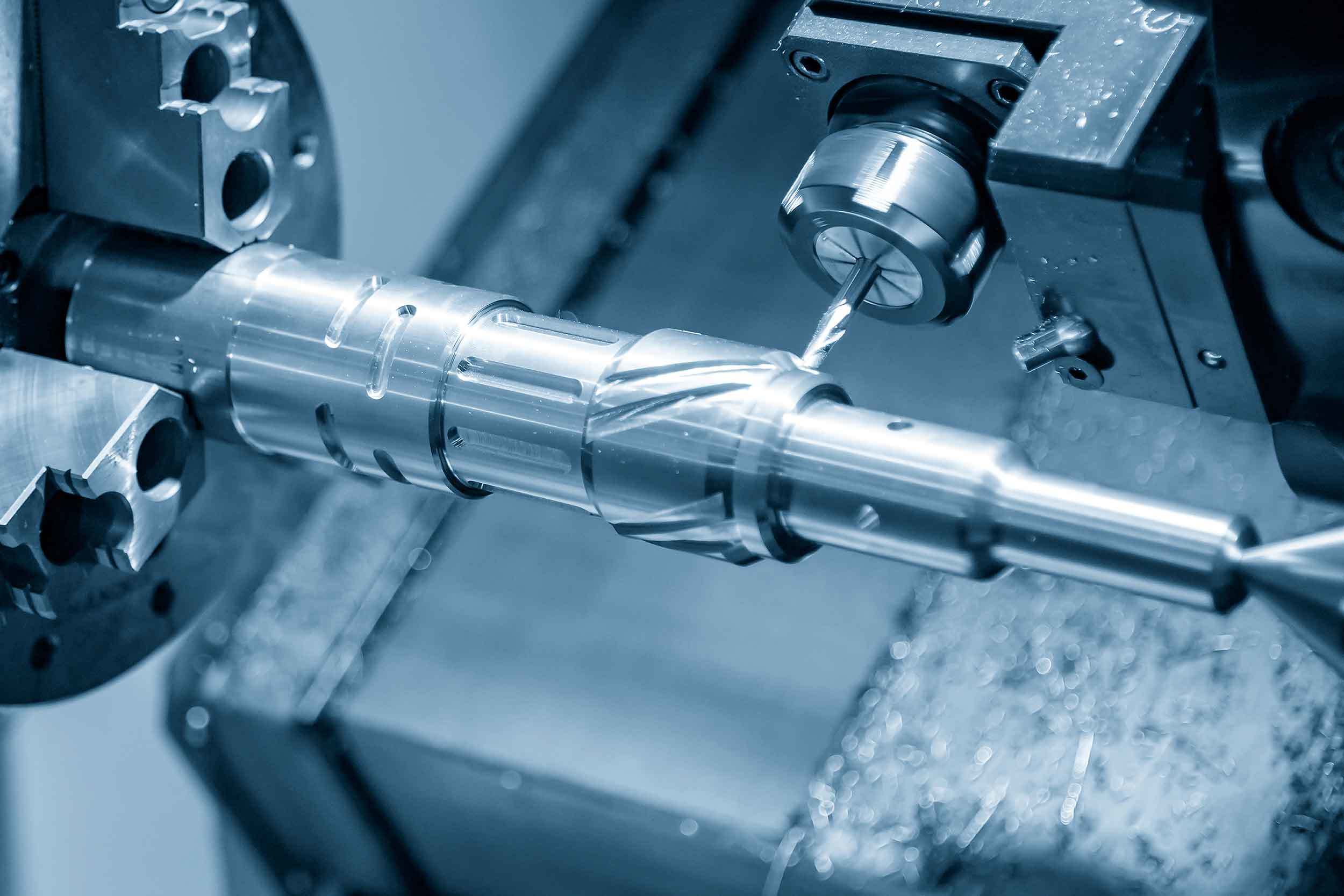

The entire production process is continuously monitored to ensure the production of high-quality parts.

In order to ensure a smooth production process, we continuously improve the production process, which is seamless and complete. With our quality management process, every process from material procurement to finished product shipment is rigorously monitored and documented.

Mechanical set-up, process inspection, and final inspection

First Article Inspection (FAI)

Statistical Process Control Report (SPC)

Production Part Approval Process Document (PPAP)

Process Research and Sampling Criteria (AQL)

Processes and processes are continuously improved

Periodic gauge gauge calibration

Insistence on "zero defects".

As an ISO certified parts manufacturer, we understand and implement the requirements of each procedure. We supervise the entire business process from customer orders, raw material receipts, first article inspections, process inspections, outsourced processing, and final finished product shipments. The quality department performs quality inspection and statistics according to the customer's inspection and sampling standards (AQL) requirements. At the same time, the relevant data files of part production and raw material batches are retained to improve traceability and provide customer evaluation and reference.

We attach great importance to the quality of our products and reflect them in every department of the company. The company constantly strives to achieve the ultimate goal of "zero defects" in its products. In response to problems encountered in production, the project leader takes the initiative to investigate the root cause and take corrective action immediately. and based on implementation, tracking and evaluation to verify the effectiveness of the measures. We continuously improve our quality system through continuous evaluation, training and commitment. Continue to work towards the goal of "zero defects".

Pre-production

The engineering and quality departments work together to create and approve production drawings. Determine the sampling frequency and detection location during mass production.

produce

After the approval of the first product, mass production, surface treatment and assembly testing are carried out according to customer requirements.

examine

Dimensional inspection (according to AQL table) and 100% visual or optical inspection instrument inspection if necessary.

deliver goods

Provide Product Conformity Certificate (COC), Raw Material Certificate and Test Report, covering the dimensions specified in the customer's drawings.

Ensure product quality

Monitor every step of the production process

Our company is certified to the ISO 9001:2015 quality standard. That's why we're constantly looking for ways to improve our products and processes. We have developed a comprehensive set of inspection and testing procedures to ensure that our products meet our customers' specifications and standards.

Keyence image measuring system

Mitutoyo Coordinate Measuring Machines

Mitutoyo Optical Comparator

Rational Optical Measuring System

Rockwell Hardness Tester

Rockwell Superficial Hardness Tester

Vickers Hardness Tester

Surfcom Surface Roughness Tester

Universal Concentricity Gages

Micrometers & Calipers

Dial Indicator

Magnifiers & Microscopes

Pin & Plug Gages

Thread Plug & Ring Gages

3-Wire Thread Measuring System

Salt Spray Tester

You guys have been an EXCELLENT supplier !

★★★★★

I am very apprecative of all the support and hard work you guys do for us in providing excellent quality parts. Thank you all Pafinal team for all you do.”

Cindy

Supply Chain Development Manager

Great support year!

★★★★★

“Thank you for offering our support with good quality and on time delivery, particularly in the difficult year 2020.

John Su

Purchasing Manager

Beijing Pafinal Precision Machinery Co., Ltd.

Email:sales@pafinal.com

Address: No. 239 Huanhe South Road, Tianjin Pilot Free Trade Zone (Airport Economic Zone), Tianjin

sales@pafinal.com:

Whatsapp:

在线客服添加返回顶部

图片alt标题设置: PAFINAL

表单验证提示文本: Content cannot be empty!

循环体没有内容时: Sorry,no matching items were found.

CSS / JS 文件放置地