Preparing for project

Once the sales department receives a new purchase order, the sales coordinator will review the purchase order thoroughly, paying close attention to quantities, drawing revisions, required delivery dates, prices, and terms and conditions. Drawing revision is the most important in verifying the process, ensuring the material, dimension tolerances and surface treatment and other technical specifications are the latest before moving to further steps.

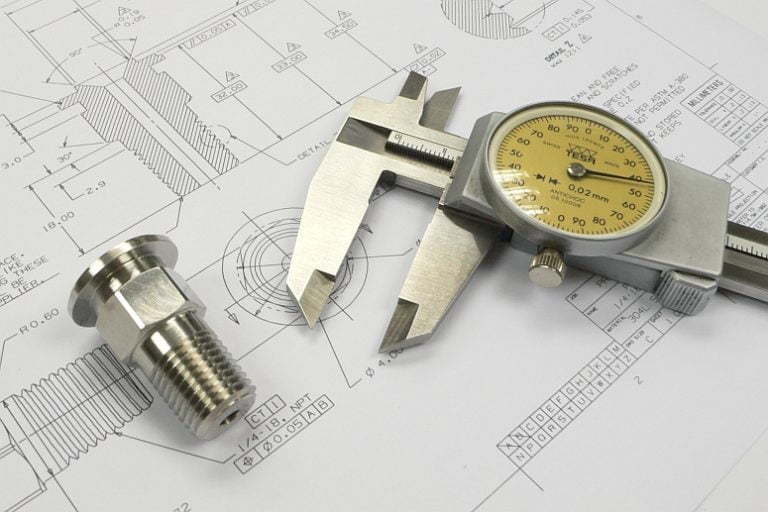

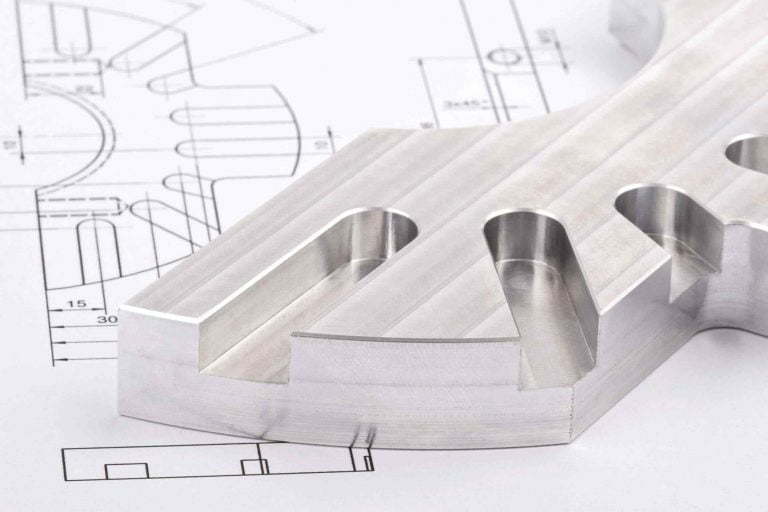

Blueprints and CAD designs

Engineers use 3D rendering software in order to produce a computer model of customer drawings and designs. This can help to reveal any potential issues that weren’t evident from the product design itself. Also takes this opportunity to return to the final design stage and deal with any problems now.

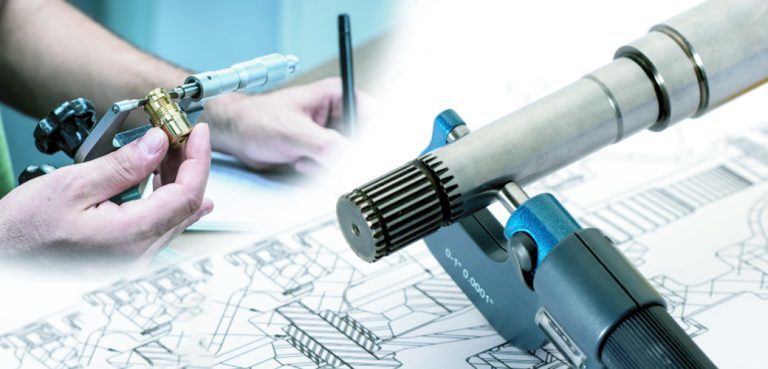

Pre-Machining Preparations

First and foremost, before proceeding to machining, preparations need to be done. For a successful custom CNC machining, the critical things necessary to be prepared are the raw materials, CNC program, cutting tools, part holding fixtures, and measuring tools. These preliminary procedures will ensure a smooth machining process.

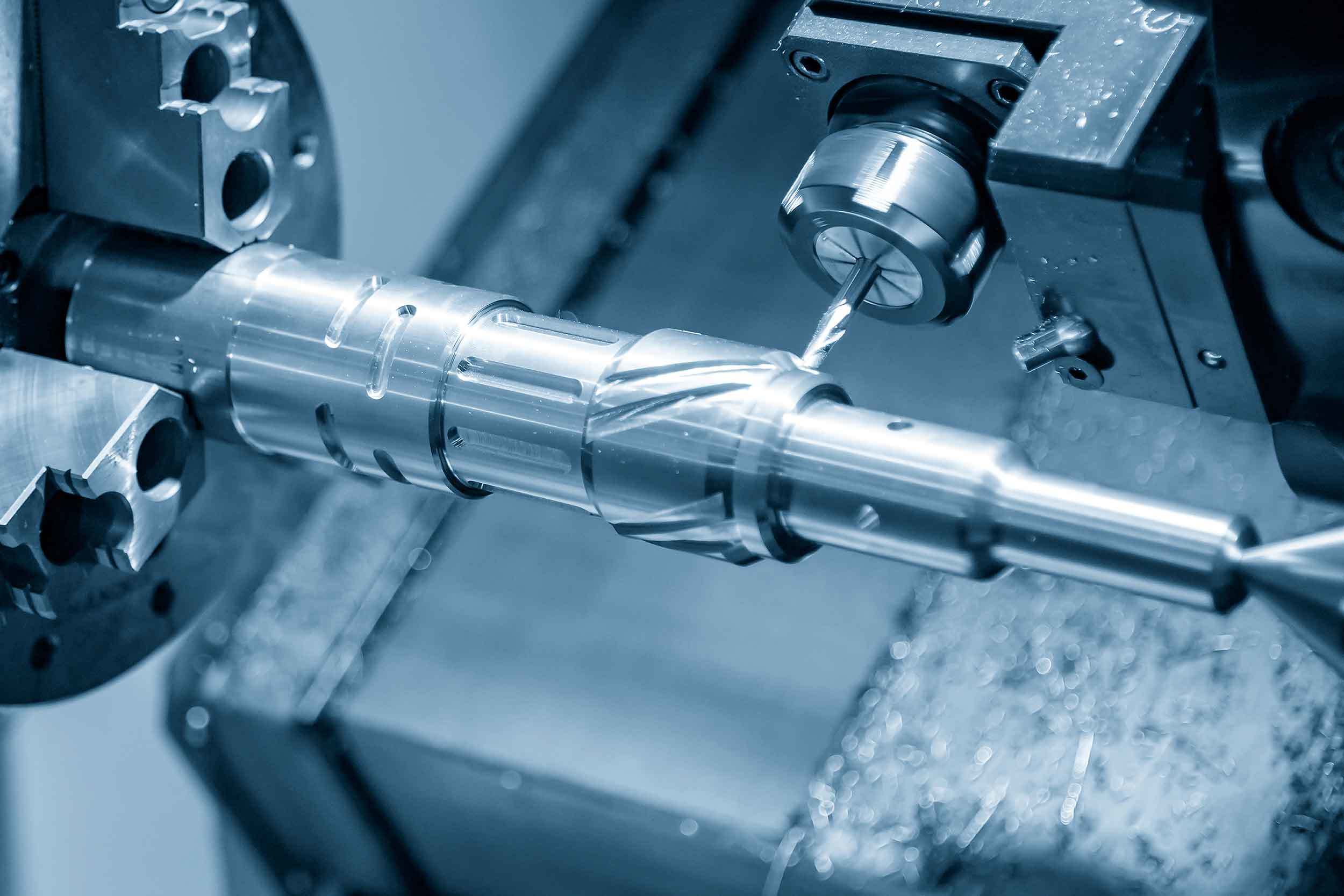

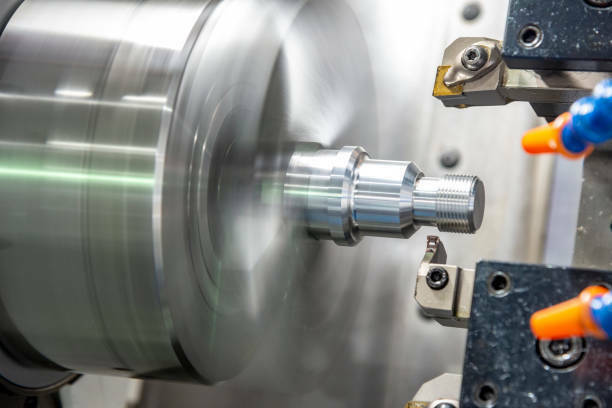

Production

Fabricating a custom part involves a series of machining processes. There are specific part features created in each of the types of machining processes. From a fundamental standpoint, the three primary operations in machining are turning, drilling, and milling. Secondary operations can be added to achieve the required shape, precision, mechanical properties, or surface finish.

Surface finishing

After the components have been formed and secondary processes have been completed, the surface treatment is a possible way to obtain sufficient resistance against environmental attack oxidation. Plating on steel and copper components can improve corrosion resistance, add decorative appeal, enhance solderability, add mechanical strength, and reduce friction. Anodizing is common for aluminum which converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish.

Assembly & Testing

The value-added assembly and testing service ensures customer specifications and functionality are met. Specific testing such as dimensional, functional operation, assembly torque & force, leak & flow testing, and electrical testing of mechanical or electrical assemblies are all performed in-house. This gives the customer the competitive advantage of purchasing ready-to-use assemblies saving their valuable internal resources.

Made to a high standard

Pafinal's production facilities are certified by an international quality management system to ensure that production facilities and quality control are maintained at the highest level. In addition, the key components for special industry applications have passed SGS securities verification and meet the industry standards of the United States and the European Uni

Focus on lean production and management

Our production lines operate under the principles of lean production and continuous improvement to increase production efficiency and reduce costs while maintaining the highest level of quality. We promote lean production management; Optimize the layout of the workshop, speed up the production time of the machine, integrate the process flow, and continue to train employees. Through lean management, we streamline the entire manufacturing and operational process to ensure that our customers receive the most competitive prices, products, and services. The production line is equipped with more than 100 CNC turning and milling lathes, CNC automatic lathes and secondary processingspecial equipment. The latest technology is used to process lathes imported from Japan to meet dimensional tolerance, concentricity, finish and geometric and position tolerances and precision machining capabilities. In addition to producing parts, we also provide assembly services to meet the specific needs of our customers. By combining multiple components manufactured by us into assemblies, we reduce the cost of post-assembly and testing for our customers. In addition, we have established seamless partnerships with material manufacturers and outsourced processors, combining their expertise to provide customers with the most stable supply chain.

- Provide solutions for metal parts for your product manufacturing

- Production of precision parts and assemblies according to drawings

- Dedicated personnel follow up from prototype design to mass production

- High-level part design, production and testing processes

- A full range of machining services

Beijing Pafinal Precision Machinery Co., Ltd.

Email:sales@pafinal.com

Address: No. 239 Huanhe South Road, Tianjin Pilot Free Trade Zone (Airport Economic Zone), Tianjin

sales@pafinal.com:

Whatsapp:

在线客服添加返回顶部

图片alt标题设置: PAFINAL

表单验证提示文本: Content cannot be empty!

循环体没有内容时: Sorry,no matching items were found.

CSS / JS 文件放置地